Apex Ammunition’s Upland Tungsten Super Shot Shotgun Shells Can Stretch Your Kill Zones

There are the great Silicon Valley legends of companies such as Apple and Hewlett-Packard getting their start in a humble backyard garage. So it should make complete sense that a producer of state-of-the-art wingshooting shells would get its start, not in an office, but on a duck hunt.

Apex Ammunition, the boutique maker of ultra-high-density Tungsten shotgun shells, is the brainchild of three Air Force buddies: Jared Lewis, Nick Charney and Jason Lonsberry. Better yet, their wives are all Air Force pilots. As it turned out, the wives of Nick and Jared were friends, and through them the guys starting hunting ducks together in January 2017.

Apex Founders (from left) Nick Charney, Jason Lonsberry and Jared Lewis.

Apex Founders (from left) Nick Charney, Jason Lonsberry and Jared Lewis.As the Apex CEO, Jason talked about how the impetus to start Apex resulted from a spectacular 60-yard shot made by Nick – that Jared and Jason had both missed.

“Nick was a hobby handloader,” Jason recalled. “First, he started with turkey loads. Then he started with duck loads. Nick was shooting tungsten. I asked him where I could get it. He said you have to make it.”

By day’s end, the three men had a business plan that would become Apex Ammunition. Their idea was based on the techniques of meticulously handcrafting ultra-high-density, non-toxic Tungsten Super Shot (TSS) shells that packed extraordinary knockdown power.

Apex shotgun shells during the handloading process.

Apex shotgun shells during the handloading process.“Our number-nine upland TSS shot hits with same kinetic energy as number-four lead and keeps its velocity higher at point of impact,” Jason noted.

At 18.1 grams/cubic centimeter (g/cc) density, APEX TSS is denser than lead (11.34 g/cc), bismuth (9.8 g/cc), copper (8.8 g/cc) or steel (7.84 g/cc), according to Apex. The higher density allows the use of smaller TSS pellets that pack a bigger payload per shell. Apex reasons that more pellets traveling in a high-density shot string produce superior stopping power on downrange quarry.

The Apex TSS non-toxic handloaded upland shotshells contain clean-burning powder and a one-piece, Tungsten-grade wad system engineered to deliver the tightest pattern possible and maximum barrel protection.

The ingredients vary with Apex’s Waterfowl, Turkey and Upland shells. The Upland shells, meanwhile, are available in 3-inch 12- and 20-gauge loads. Upland 28-gauge 2¾-inch and .410 bore 2½ and 3-inch loads are available upon request.

Jason compared their approach to making TSS shotgun shells with crafting small-batch whiskey. It was Apex’s focus on a superb consumer experience that easily justifies the premium price.

The full assortment of Apex Ammunition’s TSS shotgun shells for hunting.

The full assortment of Apex Ammunition’s TSS shotgun shells for hunting.Bottom line: the three founders wanted to make Apex the gold standard for wingshooting shotgun shells.

“We handcraft everything we do, except steel,” Jason said. “All of our TSS ammunition is loaded by hand. We load powder down to the grain. We add or remove a single pellet to meet our tolerances.”

The TSS shot is polished in a tumbler for consistency and accuracy. A press rolls and crimps each shell. The ambient temperature is controlled for maximum powder burn rate. The type of powder loaded varies with the game and application to deliver optimal burn rates and pressures. Even the packaging is custom made, with the shells arriving in a custom wood box that had a gold-colored clasp and hinges, and black confetti packing material – similar to the kind of presentation you might find in a bottle of small-batch whiskey.

Apex Ammunition handloads their TSS shot to stringent tolerances – down to a single pellet.

Apex Ammunition handloads their TSS shot to stringent tolerances – down to a single pellet.Based in Columbus, Mississippi, with a current workforce of about 20, Apex Ammunition started in February 2017 with their first product, TSS Turkey loads, which began deliveries a few months later in April. Apex Ammunition quickly followed up with their Predator/Deer shells.

“We jumped into waterfowl loads in the Fall of 2017,” Jason explained, “but that didn’t really take off until the hunting season of 2018-2019. Once the concept of TSS took hold in the spring of 2018, our waterfowl loads gained a lot more traction. That when we saw an opportunity to handcraft steel loads, which have become more popular.”

Through ongoing research, Apex Ammunition has shown that, in fact, it takes less TSS shot than steel or lead to bring down a bird because of its higher penetrating power. As an aside, their tests also revealed that the higher density of TSS made the ammunition less susceptible to the vagaries of wind.

“TSS gives you more range, is less affected by wind and has more penetrating power,” Jason summarized. “Shotgun shells are a commodity, but Apex is in the business of providing great hunting experiences.”

Come the summer of 2019, the three founders turned their attention to the creation of TSS upland shells in 12, 20 and 28 gauge. I hunted bobwhite quail with the 20-gauge loads, and saw first-hand how TSS lived up to its reputation.

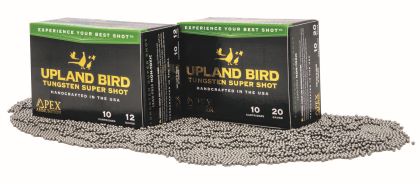

A box of Apex Ammunition’s TSS Upland Bird shotgun shells.

A box of Apex Ammunition’s TSS Upland Bird shotgun shells.We tested the Apex Upland TSS shells on a bobwhite quail hunt at Quailridge Plantation in Moultrie, Georgia. The ammunition was hand loaded with ¾ ounce of #7½ shot at a rated velocity of 1500 feet per second. Each box held 10 cartridges. The MSRP was $52.99 per box.

The shotgun of choice was a 20-gauge Beretta 687 Silver Pigeon III over/under with a custom-fitted stock by Rich Cole of Cole Gunsmithing in Naples, Florida. The shotgun had 30-inch barrels with screw-in chokes of cylinder and improved cylinder.

Quailridge Plantation encompasses some 3,000 acres of impeccably groomed quail habitat nurtured by several generations of the Norman family. You’d be hard-pressed to find a quail preserve more challenging and beautiful in the American South.

Some of the birds taken with Apex Upland TSS shells at Quailridge Plantation.

Some of the birds taken with Apex Upland TSS shells at Quailridge Plantation.The Cole Beretta Silver Pigeon III had proved its mettle on singles, doubles and coveys upwards of 30 plump quail. The birds took off like rockets, giving me the opportunity to evaluate the Apex Upland TSS shells on shots of some 60 yards, where I was able to drop the quail, following in the footsteps of Nick’s duck kill that inspired the three guys to start Apex Ammunition.

Apex’s Upland TSS downed birds with powerful authority. You could see the difference by the way that the birds collapsed on the wing when they received the brunt of the full measure of payload. It was like they were hit by sledge hammer. There were no cripples on the hunt for me that day. I either killed the quail cleanly or missed them entirely. Surprisingly, at 1500 feet per second, there was no felt recoil – meaning that the Apex Upland TSS let me quickly recover for a second shot.

It was after the hunt that I fully understood what Jason meant when he said that Apex was “in the business of great experiences.”

Irwin Greenstein is the publisher of Shotgun Life. You can reach him at contact@shotgunlife.com.

Useful resources:

Irwin Greenstein is Publisher of Shotgun Life. Please send your comments to letters@shotgunlife.com.

Comments