Important Information About Shotshell Pressures

Shotshell pressures seem to be a worrisome area for many shotgunners, especially reloaders. They worry that if they shoot excessive pressure loads that their shotgun could well “blow up.” They’ve heard that from their buddies, but they really don’t have any solid scientific evidence to support those assertions.

The first question, of course, is: Is there a problem? I would have to say by and large excessive shotshell pressures are not a problem to worry about insofar as shotguns blowing up. This assumes we are talking about non-Damascus shotgun barrels, and shotshells loaded with smokeless, not black powders.

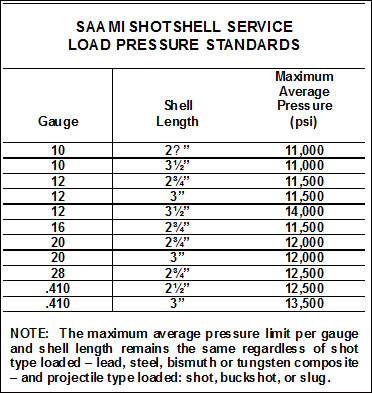

Modern shotgun barrels are built to withstand pressures many times above the maximum service load pressures developed by the shotshell loads – factory or reloaded – expected to be fired in such barrels. In this regard the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) establishes and publishes voluntary standards for the pressure levels of shotshell service loads insofar as U.S. manufacturers are concerned. The same standards apply to reloads. The pressures SAAMI is concerned with are exclusively chamber, not down-barrel pressures. The accompanying table outlines SAAMI’s current pressure standards.

The current method adopted by SAAMI for shotshell pressure measurement is to use the piezoelectric transducer system and then to express pressures so measured in pounds per square inch (psi). The old way was to use the lead crusher system and express pressures in lead units of pressure (LUP). While today all data regarding factory load shotshell pressures are measured and reported in psi, there is still some shotshell reloading data kicking around in which pressures are measured and expressed in LUP. Worry not. Both systems are valid.

The SAAMI load-pressure chart for shotshells.

The SAAMI load-pressure chart for shotshells.

Note in the table that as the gauge of shotshell loads decreases in diameter, higher pressures are permitted. This is simply an accommodation to the fact that as the square inches of the area in a shotshell decrease, the amount of pressure developed by a given powder charge to push a given shot charge weight to a desired velocity level goes up. Simply put: as the square of inches of area decreases, the pounds of pressure developed increases. Can’t get around it. So barrel manufacturers construct their barrels increasingly stronger the smaller the gauge shells to be fired in them in expectation that the pressures of such smaller gauge loads will be higher. The only exception are barrels chambered for 3½-inch, 12-gauge shells where SAAMI members elected to allow 14,000 psi max pressures 3½-inch, 12-gauge shells.

Now back to the worry that excessive pressures are going to cause shotgun barrels to blow up. While this can happen, it is rare. I once embarked under contract to Remington on a destructive testing regimen to determine how much pressure had to be developed in a Remington Model 870 12-gauge barrels chambered for 3-inch shells before they would explode.

SAAMI tells us that whether using 2¾-inch or 3-inch 12-gauge loads, the maximum allowable pressure level of such shells is 11,500 psi. In this gauge and shell lengths, by the way, SAAMI provides for a mean average of 19,800 psi proof loads for proofing such barrels. So, I started by firing loads which developed 20,000 psi in the test Remington 870 barrels. Nothing happened. I increased the pressure level to 25,000 psi; nothing happened. I continued increasing the pressure by 5,000 psi. Nothing happened even when the pressure level of the destructive testing load reached 50,000 psi! Finally, when I got to 55,000 psi I could get Remington 870 barrels chambered for 3-inch 12-gauge shells to blow up. And they would blow up spectacularly, banana-peeling into multiple segments forward of the chamber. Up until 55,000 psi the barrels wouldn’t even bulge. So we can conclude, at least, that’s how smart Remington is in building super-strong shotgun barrels to withstand excessive pressure levels.

Now let me make it clear that none of the above reporting is to encourage or to foster a blasé attitude about excessive shotshell pressures. It’s just to report that it takes a heckuva lot of pressure before a shotgun barrel will actually blow up from the pressure developed by the shotshell load itself. The vast majority of shotgun barrel blow-ups are caused not by the pressures developed by the shotshell load, but rather by obstructions in the barrel. Obstructions can take the form of lodged wads, plugs of snow or mud, etc., and are notorious for causing barrel bursts if they are not cleared before a following fresh round is fired.

Where excessive shotshell pressures generally occur is in improperly put together reloads. But these are generally mild excess pressure situations, not giantic ones involving double and triple charges of powder. However, keep in mind that mildly excessive reload pressures are continuously stressing the gun and contribute to high recoil levels. This in turn tends to eventually crack wood and begin to break little parts within the action and trigger group. So, it is never wise or safe – and nothing positive is ever accomplished – by firing modestly excessive pressure loads in any shotgun.

Copyright 2014 by Tom Roster. All Rights Reserved. This material may not be published, broadcast, rewritten or redistributed.

Tom Roster is an independent ballistics consultant and author specializing in the design and testing of shotshell loads for U.S. shotshell and reloading components manufacturers. He is a court-recognized shotshell/shotgun expert witness. Tom was formerly the Ballistics Research Director at Oregon Institute of Technology and then served as a Ballistics Specialist for the Dept. of the Interior. In these capacities he designed and administered the world’s six most extensive lead versus nontoxic shot duck, goose, pheasant and dove shooting tests ever conducted. He then co-authored their peer-reviewed scientific reports. Roster spends about 100 days afield each year testing lead and nontoxic hunting and target shotshell loads, then traveling worldwide reporting on his findings to industry and wildlife professionals, hunters and shooters, and in his writings for various shotgunning magazines. Contact him in Oregon at (541) 884-2974,tomroster@charter.net.

Tom Roster is an independent ballistics consultant and author specializing in the design and testing of shotshell loads for U.S. shotshell and reloading components manufacturers. He is a court-recognized shotshell/shotgun expert witness. Tom was formerly the Ballistics Research Director at Oregon Institute of Technology and then served as a Ballistics Specialist for the Dept. of the Interior. In these capacities he designed and administered the world’s six most extensive lead versus nontoxic shot duck, goose, pheasant and dove shooting tests ever conducted. He then co-authored their peer-reviewed scientific reports. Roster spends about 100 days afield each year testing lead and nontoxic hunting and target shotshell loads, then traveling worldwide reporting on his findings to industry and wildlife professionals, hunters and shooters, and in his writings for various shotgunning magazines. Contact him in Oregon at (541) 884-2974, tomroster@charter.net.

Comments