Why Gun Specific Patterning Geometry Delivers Superior Shotgun Choke Performance

When I invented and patented my Featherlite Chokes for clay target sports, thankfully I went through a major learning curve about how shotguns truly performed when it came to patterns and chokes. Whether the gun was a fixed choke barrel or came with choke tubes, I quickly realized that they all patterned differently and depending on what geometry that particular choke had inside. This Gun Specific Patterning Geometry (G.S.P.G.) made all the difference when it came to pattern consistency, pellet counts, evenness and shot to shot deviations.

Not only did I learn that each gun shot differently, I also learned that once the choke tube for that particular shotgun was made to the best possible geometries the ammunition became less finicky; in other words, ammo that usually got a bad rap for lousy patterns now became much better. I quickly came to realize that ammo was only a small percentage of the issues people were experiencing and complaining about: it was actually more times than not the choke tube being used.

Once I determined this through thousands of rounds of testing using 20 different gun makes and models with 13 different bore diameter barrels, I discovered exactly how important choke materials and geometries are, and my patented Featherlite Muller Choke Tubes were born and continued to revolutionize clay target sports in a very short two-year period.

Fast forward a few years and realizing how critically important lessons in ballistics were, I knew someday I would use my same knowledge and discoveries to create the most efficient waterfowl/hunting choke tube on the market. That time has come and I have done it. Through comparison testing with all ammunitions on the market with all choke tubes currently on the market and all the shotguns being used to hunt with all over the U.S.A. and Canada, I have invented and developed perhaps the most efficiently patterning choke for waterfowl hunting based on my research in (G.S.P.G).

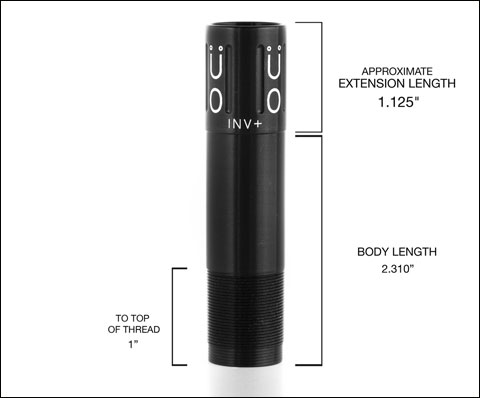

The proportions of a Muller Featherlite choke.

With Muller Chokes’ G.S.P.G., we are now able to shoot a much larger pattern to achieve amazing, lethal results at very long distances like never before. Due to the even pellet distribution throughout the pattern on each and every shot, the bird gets hit by many more pellets to produce deadlier hits with far less cripples at extreme distances.

Not only does our kill-to-cripple ratio go way up, but also our hit-to-miss ratio goes through the roof. Before Muller Chokes came to market, all the “good” chokes (or well-known) chokes on the market mostly shoot with a “Hot Core” pattern which means most of the pellets in your shot shell are concentrated inside the center 20 inches. If you happen to be right-on within this 20 inches, most targets/birds would be smoked, which is a good thing…right? Well, sort of, but here’s where the problem is with those popular chokes that shoot a hot core. We are not usually “right on” when shooting a moving target (as much as we want to think we are), so what happens as a result of being off “a little” is a high percentage of crippled birds.

The reason this happens is because with a hot core patterning choke, most of our pellets are concentrated on that inner 20 inches so the remaining outer fringe of our 30” pattern is horribly scarce and does not have enough pellets out there to effectively kill a bird at the distances that choke and ammo are intended for.

And, as we all know, crippled birds are a hunter’s worst nightmare. Not only do we know it is inhumane, but we can end up losing our meal and our trophy and spend countless hours chasing cripples and, bottom line, spoiling a hunt.

Now, as for the other chokes on the market that are said to be well known or good that do not shoot a hot core, I found that some of these are actually even worse than a hot core pattern because these generate what I like to call a worthless pattern or blown pattern. This happens when one of two things occurs: either the geometry in that choke is far from what that particular gun likes, or the constriction amount is simply too tight for the ammo being used. Either the shot size is too large or the velocity is too fast or the payload is too heavy, or a combination of all three. These two types of conditions are not OK to hunt with.

What happens with these patterns is basically they have large voids in them; the pellets are spread out too far apart and each and every shot is vastly different, which is called “shot-to-shot deviation.” These patterns are sometimes so horrible that they are incapable of a clean kill even at 25 yards.

Since most shooters/hunters do not pattern their chokes and loads, they are not aware of the problem. Instead, they go to a larger shot size which makes things worse in regards to pattern density, because the pellet energy increases, they start to knock birds down and feel that going with larger shot size is key, whereas it is the opposite of what we should be doing.

With my ballistics expertise, I was able to correct these problems – enabling me to develop the only “No Limits” hunting choke tube anywhere. “No Limits” means you can shoot any shotshell you choose with confidence.

A detail of the tough Cerakote finish on the Muller H2O Waterfowl and Hunting Chokes.

“No Limits” also makes the Muller H2O Waterfowl/Hunting Chokes a stand-out in the marketplace. I apply the same G.S.P.G. to every choke for each and every gun make and model until the patterns of that particular gun deliver the lowest deviation shot-to-shot. Any shot size, any pellet material, any payload, any velocity and any wad style.

The rust-proof Muller H2O Waterfowl/Hunting Chokes are actually harder than your shotgun barrel. With “No Limits” they have three constrictions, a 60-day money back guarantee and a non-glare Cerakote ceramic finish, so they look really cool in the end of the gun, but above all that, the most important key is performance.

To prove they are the best, “No Limits” also includes a 60-Day No Risk Money Back Guarantee on Muller Chokes. You shoot it for two months and if you don’t feel it is the best, just simply send it back for a full refund.

Jimmy Muller is Inventor and Founder of Muller Chokes. NSCA Master Class shooter

FITASC, Sporting Clay and 5-Stand Competitor. Find out more about the extraordinary Muller Chokes at www.mullerchokes.com

Jimmy Muller is Inventor and Founder of Muller Chokes. NSCA Master Class shooterFITASC, Sporting Clay and 5-Stand Competitor. Find out more about the extraordinary Muller Chokes at www.mullerchokes.com

Comments