Legacy Sports International Shows Us How Cerakote is Done

We tend to associate embellished shotguns with extravagant engravings of pastoral bliss rendered in masterpieces of steel. But head down-market to the other 99 percent and you can order a field or clays shotgun personalized with your own visual flash for about $600.

Your budget alternative comes courtesy of the same coatings that protect your shotgun against the elements and handling, and applied on the Turkish-made Pointer semi-automatics sold and customized by Legacy Sports International in Reno, Nevada.

I visited Legacy Sports International in early 2020 to learn about the largest Cerakote and hydrographics gun finishing operation in the U.S., as asserted by Andy McCormick, the company’s Executive Vice President of Marketing and Sales.

These robotic arms spray Cerakote at Legacy Sports International.

These robotic arms spray Cerakote at Legacy Sports International.The scale of their firearm beautification operation belies its street-level appearance. The Uber driver dropped me off at an unmarked building with black-out windows in a sprawling industrial park about 20 minutes from downtown Reno. Double-checking to see if I had arrived at the right place, the building looked deceptively small. Inside, the compact reception area presents a high-tech visitor registration. Glance down the narrow corridor to your right and it looked like rows of offices. But behind the receptionist’s desk is an ordinary door that could easily pass for a coat closet. I would discover later it opens to a cavernous 50,000-square-foot warehouse where all the visual magic happens.

From the reception area Mr. McCormick led me into his office. A gregarious guy and avid hunter, you can tell the immensity of his workload by the two oversized computer monitors that dominate his desk. That’s largely because “international” is the operative word in the company’s name.

Andy McCormick

Andy McCormickLegacy Sports International imports, distributes and markets Pointer shotguns from Turkey, Howa rifles from Japan, Nikko Stirling scopes from Shanghai, Hardy Rifles from New Zealand, Citadel handguns from the Philippines and rifles from Brazil, as well as Take Aim targets from the U.S. For the most part, Legacy’s supply chain touches cost-conscious price points where Cerakote and hydrographics can differentiate their semi-automatics and rifles from the monochromatic legions on retailers’ shelves.

Ever bought a ticket to fund-raiser where the auction guns have eye-popping graphics or colors? Chances are the gun made a transformative stop at Legacy Sports International. When it comes to customization, the company’s Conservation Partners Program includes Ducks Unlimited, National Wild Turkey Foundation, Delta Waterfowl, Pheasants Forever, Ruffed Grouse Society, California Waterfowl, the National Rifle Association, Safari Club International and the Mule Deer Foundation as well as others.

A technician at Legacy Sports International helps float a hydrographics camo pattern before it’s submerged and applied to the shotguns.

A technician at Legacy Sports International helps float a hydrographics camo pattern before it’s submerged and applied to the shotguns.“When you do as much as we do with conservation groups, we can customize the guns with logos and colors to give them a higher perceived value at the event,” Mr. McCormick explained. “We focus on conservation groups more than many of our competitors do.”

Given that the Cerakote and hydrographics operation has received ISO 9001 quality management certification, the Reno Cerakote operation can work on military contracts as well.

At the outset, Legacy Sports International had outsourced the Cerakote finishing on 1911 handguns. As the business grew, Legacy’s management team realized it needed tighter quality control, especially when it came to tolerances between individual parts, which in a firearm like the 1911, can prove mission critical. Although most Cerakote applications are about 0.001-inch thick, it could be just enough of a skim to affect assembly and performance.

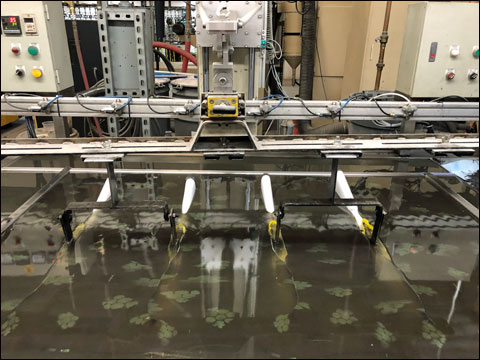

During the hydrographics process, white-primered shotgun stocks are lowered on arms into the water as the pattern is applied.

During the hydrographics process, white-primered shotgun stocks are lowered on arms into the water as the pattern is applied.“We have tight tolerances already,” said Mr. McCormick.

Legacy Sports International brought Cerakote in-house beginning January 2015. (Legacy Sports International started in 2000). The division has been steadily growing. Today, the company applies their coatings on 300 to 500 semi-automatic shotguns every two weeks. At those volumes you’d expect the process to be fully automated. In fact, except for the curing and drying, people are involved in nearly every step of the high-touch process.

Cerakote was developed by NIC Industries of Oregon in the 1980s to protect firearms against abrasions, corrosion and weather. It’s composition of ceramic and polymer works especially well on firearm materials such as aluminum, polymers and steel. Cerakote also has inherent lubricant properties. Available in more than 100 colors, Cerakote ignited a gun-art movement of brilliant hues and bold imagery.

During my tour of the Cerakote and hydrographics operation with Mr. McCormick, I saw that Cerakote approximates the consistency of motor oil. Its application can be tedious and time consuming, with virtually no margin of error. That’s why NIC Industries cautions that Cerakote is not a do-it-yourself project.

After the guns are disassembled and their finish stripped, a primer is applied with a spray gun prior to the Cerakote application.

After the guns are disassembled and their finish stripped, a primer is applied with a spray gun prior to the Cerakote application.For starters, the firearm must be completely disassembled. Next step is degreasing to avoid contamination. Cerakote is then applied using a high-volume, low-pressure (HVLP) spray gun. The trick, though, is finding and training someone capable of applying the exact thickness of the coating, so that the finish won’t hinder final assembly and operation. After the application, metal parts are oven-cured at 250-degrees while polymer components are oven-cured at 150 to 180-degrees. NIC Industries claims the completed Cerakote gun is good for 3,500 hours without rust or corrosion.

A Cerakote curing oven at Legacy Sports International.

A Cerakote curing oven at Legacy Sports International.At Legacy Sports International, the Cerakote and hydrographics equipment share the same area in the warehouse in a space that holds about 24 different pieces of equipment.

Hydrographics is a form of water-transfer printing through immersion in a large tank. Because it uses a thin image film that can be compared to a decal, the technique lends itself well to three-dimensional surfaces.

As with Cerakote there’s disassembly and surface preparation stages. A polyvinyl alcohol hydrographic film printed with an image is delicately floated on the surface of a big water tank. The hydrographic film is water-soluble and dissolves. The shotgun stock, for example, is placed on rack that’s slowly lowered into the water – allowing the image to adhere to every nuance in the shape of the stock. The residual film is rinsed away, leaving the image. The piece is left to air cure. Afterwards, clear coat is applied. Although the image may sound flimsy, in fact hydrographics are quite durable.

The bench where the guns are reassembled after the Cerakote or hydrographics process.

The bench where the guns are reassembled after the Cerakote or hydrographics process.“Our ability to bring these guns to market as fast as we do, from idea to completion, takes 60 to 90 days,” Mr. McCormick explained. “We’re always implementing new colors and styles.”

As an aside he mentioned that Legacy Sports International doesn’t work on individual pieces. “Now we’re doing mostly special projects.”

So next time when you’re visiting the local gun store and see rows of black and gray semi-automatics remember: think outside the box.

Irwin Greenstein is the publisher of Shotgun Life. You can reach him at contact@shotgunlife.com.

Useful resources:

The web site for Legacy Sports International

Irwin Greenstein is Publisher of Shotgun Life. Please send your comments to letters@shotgunlife.com.

Comments