Beretta’s Izumi Project Joins Italian and Japanese Artisans in a Remarkably Matched SO6EELL Shotgun and Samurai Dagger

It took five years to complete, but the vision of Franco Gussalli Beretta and Master Izumi Koshiro was ultimately unveiled on February 5, 2015 at the Safari Club International Convention in Las Vegas.

Kept under wraps as the Izumi Project, the undertaking involved virtuoso craftsmen on two continents. Together they produced a one-of-a-kind Beretta SO6EELL sidelock shotgun and Samurai Tanto dagger, both engraved by Master Izumi Koshiro, who by all accounts is the greatest living Japanese sword engraver.

The Izumi Project Beretta SO6EELL.

The Izumi Project celebrates “Wa,” an ancient Japanese principle of harmony that fused the noble antiquity of forging Japanese swords with Beretta’s 500-year-old heritage of firearms manufacturing.

The collaboration between Mr. Beretta, who is Vice President and Managing Director of Fabbrica D’Armi Pietro Beretta S.p.A. and Executive Vice President of Beretta USA, and Mr. Koshiro of Japan, engendered a dragon theme to symbolize power and protection to the owner and his family.

Mr. Beretta described the Izumi Project as an “homage to beauty, to craftsmanship, to passion, and to the pursuit of perfection, which drives our Premium Guns philosophy.”

A detail on the Izumi Project Beretta SO6EELL receiver.

Mr. Koshiro embellished the Beretta SO6EELL receiver with two kinds of gold-inlaid dragons: a Sea Dragon on the right and a Celestial Dragon on the left. Both are depicted bursting from waves pursuing a miniature golden sphere known as the Dragon Ball or the Sacred Pearl, which represents wisdom (Yang energy) in early Taoism.

The Beretta SO6EELL is a flagship shotgun from the Beretta Premium collection. It’s a true sidelock engineered into a low-profile receiver for optimal handling. A rugged cross-bolt locking system ensures durability. The SO6EELL barrels are constructed from cold-hammer-forged Boehler Antinit steel for exceptional strength, accuracy and corrosion resistance. Beretta tests each set of barrels for ballistic performance and consistent shot patterns. The ventilated rib is file-cut. The shotguns are fitted with the finest briar walnut. The Izumi Project SO6EELL has 30-inch barrels and weighs 8½ pounds.

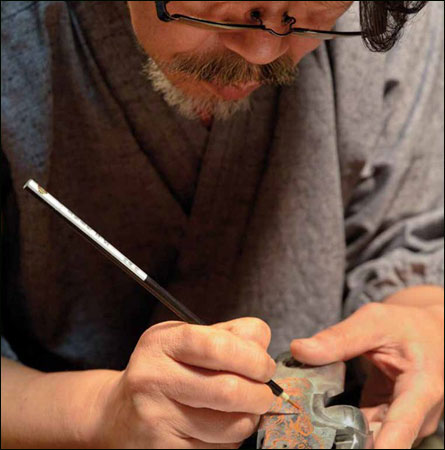

The stunning detail rendered by Mr. Izumi Koshiro on the Beretta SO6EELL.

The fire-breathing dragons on the Izumi Project SO6EELL also serve as a metaphor for the forge, which figures prominently in Samurai sword making and Beretta’s history. Beretta’s 16th century forging house in Ome, Italy — located less than an hour’s drive from the Beretta factories in Gardone Val Trompia — is the original site where Maestro Bartolomeo Beretta fabricated the company’s first gun barrels in 1526. Still operational, the Ome wood-fired forge was recently used to create a Beretta SO10 shotgun with Damascus steel sideplates and a side-by-side hammer shotgun with Damascus steel sideplates, trigger guard, top lever and external hammers. Both guns were built for Pietro Beretta

Izumi Koshiro

Mr. Koshiro said that he enthusiastically accepted Beretta’s proposal because “nowadays the superior quality of Japanese craftsmanship is at a turning point, and there are not so many successors, so it is essential to magnify and pass on, to the future generations, the art of the Samurai sword.”

Techniques used by Mr. Koshiro varied from traditional shotgun engraving as we know it. He employed Shitabori (preliminary painting), Hori (chiseling), Zogan (gold inlay), Kebori (chipping), Uchidashi (bossing), Namekuri (scaling) and Migaki (polishing).

The Izumi Project Tanto dagger.

Crafting the museum-quality Tanto dagger involved five highly regarded Japanese masters, or sensis — a respectful appellation bestowed on venerated teachers of a trade. Izumi Sensei fashioned the engravings and carvings. Ito Sensei forged the blade. Ikeda Sensei sharpened and polished the blade. Iiyama Sensei created the sharkskin grip. And Oyama Sensei finished the piece with traditional lacquer.

The shotgun and dagger are housed in a magnificent wooden box designed and crafted in London by David Linley. Fine marquetry inlay featuring a colorful dragon decorates the top of the box. A secret drawer reveals a luxury cleaning kit handmade by Italian artisan Maurizio Cairola.

The Izumi Project box by David Linley.

The Izumi Project showcased Beretta’s SO6EELL in a new light. The SO6EELL is often adorned with the finest hand engraving from Beretta artisans that depict floral motifs, game scenes, delicate English scroll, mythological images and elaborate custom designs. A minimum of 120 hours are put into each one of their engravings but custom assignments can exceed twice that time and cost more than $100,000.

While anybody with the resources can order a Beretta’s SO6EELL, only one will ever be built for the Izumi Project.

As of the SCI introduction, the Izumi Project SO6EELL, Tanto dagger and box were available for $200,000 at the Beretta Galleries in New York and Dallas.

Irwin Greenstein is the Publisher of Shotgun Life. You can reach him at contact@shotgunlife.com.

Useful resources:

The Beretta SO6 EELL Izumi Project web site

The Beretta SO6EELL Izumi Project

The Beretta SO6EELL Izumi Project catalog

The Beretta Premium web site

Irwin Greenstein is Publisher of Shotgun Life. Please send your comments to letters@shotgunlife.com.

Comments